Development Test and Qualification

Development Test and Qualification

Development Test and Qualification is a critical element in ensuring that defense products are designed right. Technology must be tested to verify the performance against the specified requirements and ultimately enable successful validation by the customer later in the lifecycle. In fact, Development Test and Qualification is the keystone in the transition from development to implementation in the Systems Engineering V.

But test and qualification can be costly and time-consuming. To minimize risk during test and stay on schedule, program teams have many things to consider; test plans need to be developed, test procedures need to be created, test facilities need to be reserved, fixtures and test equipment may need to be developed and built.

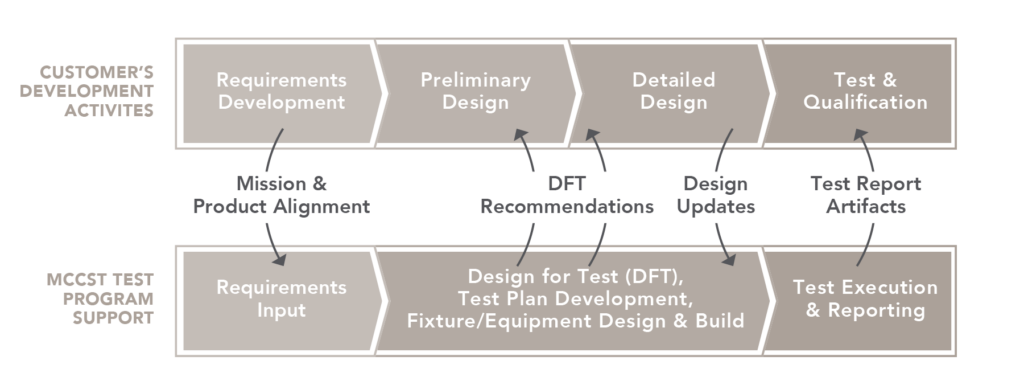

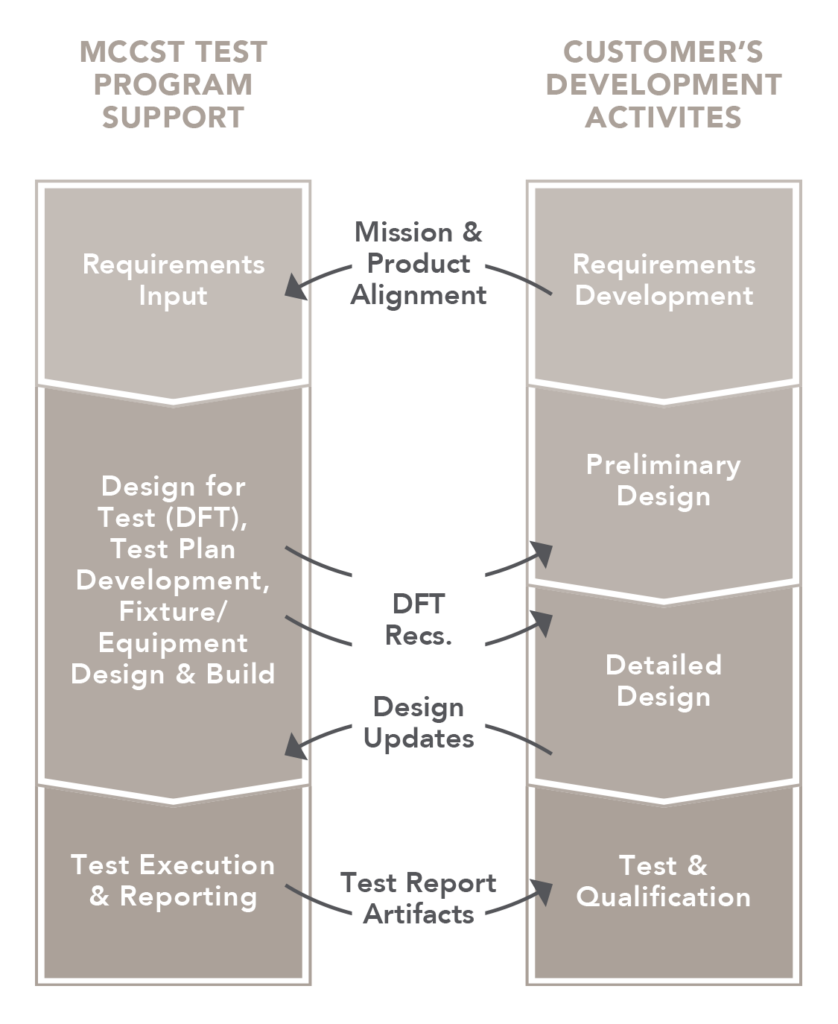

That’s where MCCST can help. We have the expertise to do the heavy lifting on the test and qualification engineering activities while our customer’s engineering team stays focused on the design of their product. With MCCST working the test planning and preparation in parallel with the development of the product, MCCST can provide valuable Design-For-Test (DFT) input to our customer’s engineering teams to ensure successful testing down the road. This gives the customer’s bandwidth to address the engineering details, while still ensuring that the test protocols, assets, and plans will be ready to go at test time.

MCCST is uniquely qualified to provide Development Test and Qualification support by providing:

MCCST is uniquely qualified to provide Development Test and Qualification support by providing:

Focused Technical Expertise

Focused Technical Expertise

- Detailed understanding of development engineering of defense products

- First-Hand Experience in MIL-STD test methods

- MCCST is well versed with environmental test specifications including:

- MIL-STD-331

- MIL-STD-810

- MIL-STD-461

- RTCA DO-160

- First-hand experience in RTCA and SAE-approved test methods

- Development of well-constructed qualification and test documentation

- In-house team of engineers and designers dedicated to equipment design & build:

- Environmental test fixtures

- Test support equipment

- EMI/EMC test cable design

- System response modeling to ensure acceptable performance during high shock and acceleration loads.

Agility and Timeliness

Agility and Timelines

- Small Business Agility

- Rapid Response Capability

- Test Documentation done in Parallel with Customer Engineering Activities

Our Engineering Team at MCCST operates in parallel with our customer’s engineering team. By engaging MCCST our customer’s enable their internal teams to focus on their product design while MCCST handles the test preparations.

MCCST’s Approach to Development Test and Qualification Support

MCCST’s Approach to Development Test and Qualification

Support

Planning

Planning

- Test requirements identification

- Program management and resource planning

- Develop test plans

- Identification of test labs

- Develop detailed test procedures

Execution

Execution

- Build/procure fixtures and support equipment

- Schedule test labs

- On-site management of tests

- Meticulous data acquisition

- Build/procure fixtures and support equipment

- Schedule test labs

- On-site management of tests

- Meticulous data acquisition

Follow-Through

Follow-Through

- Test report preparation

- Failure Reporting and Corrective Action System (FRACAS)