System Engineering

System Engineering

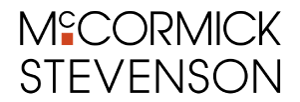

The System Engineering [SE] function is involved in all aspects of product development; from Concept to System Validation. At McCormick Stevenson we use the conventional “System Engineering V” as the foundation of our product development process. We specialize in helping our customers with the left- hand side of the V but also take a holistic view of the entire process. From experience we know it’s critically important to take into account the back-end of the process and verify that you’re able to meet all requirements.

A Design Mission to Reduce Costs

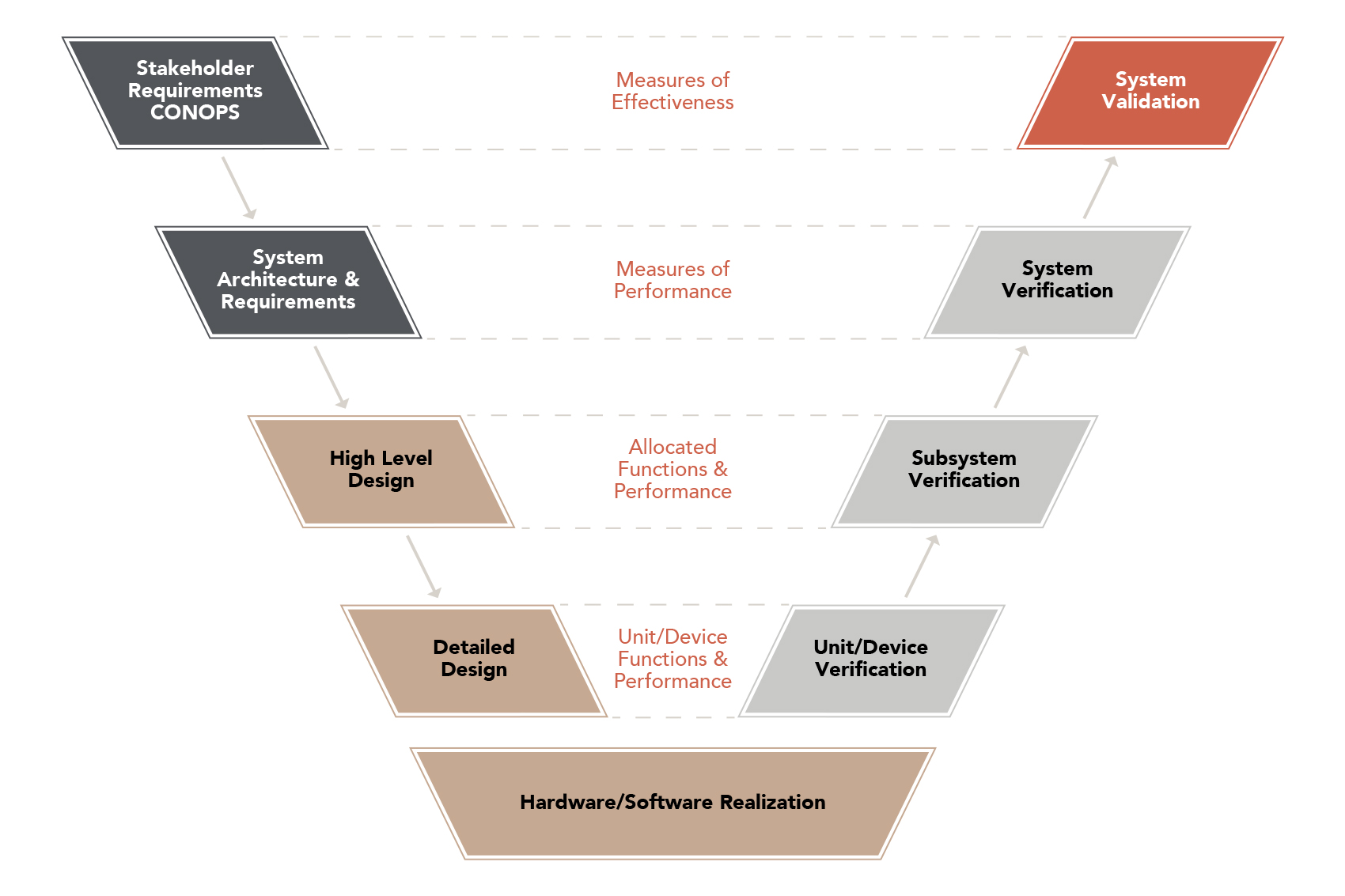

Work performed during the first three steps of the V (requirements development & design synthesis) has a profound impact on the lifecycle cost of a product. And, the further along the V you go, the more costly it becomes to address if issues arise late in the product lifecycle.

McCormick Stevenson helps Manage Cost by:

- Identifying clear, comprehensive, testable requirements

- Confirming hardware architectures are easy to manufacture and maintain

Chart Source: Jackson, Jr. Harry K. & Frigon, Normand L., Achieving the Competitive Edge, John Wiley & Sons, New York, NY, 1996.

Stakeholder Collaboration is a Key Strength

System Engineering requires extensive collaboration among all stakeholders [Government, Contractor, and Sub-Contractors]. By maintaining an open dialogue, McCormick Stevenson develops an economical, robust, testable design that fulfills customer & user expectations.

DOD Key Reviews and Audits

McCormick Stevenson performs all the key reviews and audits required by the Department of Defense (DoD)’s standard approach, including:

- SRR – System Requirements Review

- SFR – System Functional Review

- PDR – Preliminary Design Review

- CDR – Critical Design Review

- IDR – Interim Design Review

- DRR – Design Readiness Review

- TRR – Tests Readiness Review

- SVR – System Verification Review

- FCA – Functional Configuration Audit

- PCA – Physical Configuration Audit

- PRR – Production Readiness Review